- Joined

- Apr 28, 2012

- Messages

- 21,004

- Reaction score

- 10,102

- Gender

- Undisclosed

- Political Leaning

- Undisclosed

You're the one who did all the work. You earned your coffee. Looks great.Thanks!

Last edited:

You're the one who did all the work. You earned your coffee. Looks great.Thanks!

Regardless, what you did looks pretty damn good to me.That is extremely useful to know. I'll check around to see if I have a dedicated rip blade lying around, but I don't think I do.

Okay, I don't have a dedicated rip blade so I'll definitely need one for future dado-like cuts. What kind of blade is good for this? Is there a finishing blade or anything in particular I should be looking for?Sounds like you're using a combination blade. If it's got 60 teeth it's pretty definitely a combination blade or a crosscut blade. Thin kerf is it?

A rip blade would have flat teeth. Maybe an 1/8" or so wide tip and flat there.

"For flawless rips and glueline joints."If I understand your predicament, you need to leave a flat bottomed kerf.

View attachment 67366809

I've become the go-to fixit guy in the family, though they can overestimate my value now and again. One time they asked me if they should be concerned with a long crack in their ceiling, and I was like, "Yyyyeahhhh, you're gonna want a professional carpenter to look at that one."Very nice work. Not bad for a home repair.

Years ago I repaired cracks in the ceiling drywall at a friends mother's house. Came out ok. Had to notch out the crack, fill , sand , tape and blend in the mud, texture and paint.I've become the go-to fixit guy in the family, though they can overestimate my value now and again. One time they asked me if they should be concerned with a long crack in their ceiling, and I was like, "Yyyyeahhhh, you're gonna want a professional carpenter to look at that one."

Well if the ceiling crack is just settling then that's fine. Problem is that I'm not the guy to determine if it's settling or something legitimately serious.Years ago I repaired cracks in the ceiling drywall at a friends mother's house. Came out ok. Had to notch out the crack, fill , sand , tape and blend in the mud, texture and paint.

Not my cup of tea.

Last project I did a year ago was repair a bathroom drawer that my daughter had pulled the front off. Cheap material. Ended up just making a new drawer out of cabinet grade plywood and reusing the drawer front.

Again, well done on your repair.

By the way, I think you might be about the third person in this thread to tell me to dowel the piece together. By this do you mean drilling holes in the two pieces so that dowels can be used as interior joiners, so that they can't be seen from the outside?You have a planer? You want to use glue and dowel to make a solid piece. That's what I would do. I would use a planer preferable with an adjustable square corner guide to bring it to the dimension I wanted then do as you planned to except using the wood dowels and glue to fasten the piece.

Yea, that way you have besides the adhesive bond on one surface of the part, and you have a mechanical bond as well. The part in your case was too thin to do that once I realized exactly what you intended. The holes wouldnt come from the outside they would be interior only. The other thing would be a biscuit style joint. Where you make slots for a wood biscuit to glue and fit. Also not a good choice for your project. The parts being joined if they are going to be used need to have some meat on them. What you were doing is basically a thick veneer. Which was why I realized those types of joints were inappropriate for your project.By the way, I think you might be about the third person in this thread to tell me to dowel the piece together. By this do you mean drilling holes in the two pieces so that dowels can be used as interior joiners, so that they can't be seen from the outside?

It never ends, does it."For flawless rips and glueline joints."

That's the one! Man, that would have spared me a major headache if I had had that. Live and learn.

Okay, I don't have a dedicated rip blade so I'll definitely need one for future dado-like cuts. What kind of blade is good for this? Is there a finishing blade or anything in particular I should be looking for?

By the way, I think you might be about the third person in this thread to tell me to dowel the piece together. By this do you mean drilling holes in the two pieces so that dowels can be used as interior joiners, so that they can't be seen from the outside?

I haven't been at this long enough to have a favorite brand yet. I have a hitachi 70 tooth which was pretty decent until I needed to clean it, and while it was soaking in Super Clean I swapped it out with the Diablo 60 tooth. Cleaning the Hitachi stopped the burn marks, but I put it on my miter saw so I still haven't done a clean test (comparing a clean hitachi 70 tooth to a clean diablo 60 tooth). .I buy Freud or Forrest Wood Worker II blades for my dedicate wood shop equipment.

If I need a fairly decent big box store blade in a pinch, I'll use a Diablo and have been impressed with them.

I haven't been at this long enough to have a favorite brand yet. I have a hitachi 70 tooth which was pretty decent until I needed to clean it, and while it was soaking in Super Clean I swapped it out with the Diablo 60 tooth. Cleaning the Hitachi stopped the burn marks, but I put it on my miter saw so I still haven't done a clean test (comparing a clean hitachi 70 tooth to a clean diablo 60 tooth). .

I was forced to switch out blades because I was getting crazy saw burn, until I realized it was a combination of a dirty a blade and the blade being ridiculously out of alignment to the fence.

I got a dial gauge for the purpose, and unfortunately I'm absolutely unable to get the blade better than 8/1000th's in alignment. And I can't find a youtube tutorial on aligning a Bosch jobsite saw. The manual is completely unhelpful.

Until I figure this problem out, I'm unwilling to build a superior cross cut sled I've had planned for a while, because if my blade isn't even aligned, what's the point?

I haven't been at this long enough to have a favorite brand yet. I have a hitachi 70 tooth which was pretty decent until I needed to clean it, and while it was soaking in Super Clean I swapped it out with the Diablo 60 tooth. Cleaning the Hitachi stopped the burn marks, but I put it on my miter saw so I still haven't done a clean test (comparing a clean hitachi 70 tooth to a clean diablo 60 tooth). .

I was forced to switch out blades because I was getting crazy saw burn, until I realized it was a combination of a dirty a blade and the blade being ridiculously out of alignment to the fence.

I got a dial gauge for the purpose, and unfortunately I'm absolutely unable to get the blade better than 8/1000th's in alignment. And I can't find a youtube tutorial on aligning a Bosch jobsite saw. The manual is completely unhelpful.

Until I figure this problem out, I'm unwilling to build a superior cross cut sled I've had planned for a while, because if my blade isn't even aligned, what's the point?

The .008 mis-alignment is unfortunately a pinch at the back, and it’s actually in relation to the miter slot; not the fence. Sorry, my bad. (I attached the dial gauge to a piece of hardwood to fit snug in the miter slot). This is comparing the same tooth in the front as in the back (marking it with a marker). I’ve tackled this issue four times now, and during the last attempt came to think that if the problem is this insanely difficult, the saw housing itself just may not be built properly or there’s more to it than merely loosening the bolts to the housing and pushing on the blade as the manual says. I’ve even had my wife pushing on the saw while I re-tightened the bolts so it didn’t push back into place (doesn’t work). While tightening the bolts, you can watch the dial gauge return to .008 (the bad kind of .008; not the good kind). So I can align the blade when he bolts are loose, but when I tighten them….that’s it…game over…it returns to mis-alignment.Yes sir!

1. Alignment

2. Sharpest blade you can find.

You can allow .008 with the rip fence tailing away from the blade, but never allow any tail in towards the blade. The reason I don't fret over very minor tail out is because some gnarly grained woods actually spread once they pass the blade because the fibers release from each other. And obviously, you don't want tail in because it can pinch the stock creating a possible kick back situation.

.008 to the miter slot is pretty good regardless of what some of the lumberjock perfectionists say. I know guys that accept .015

The rip fence is why I always used my Ridgid over the Bosch because it's a much beefier fence and can handle tons of jobsite abuse, but that doesn't help you much.

The Bosch 4100 series rip fence is a tad trickier than the Ridgid. Align the fence to the closest miter slot and not the blade. First, you need to lock down the rip fence and take a reading, then release and lock it down again and take another reading. Do this several times over again and see what the tendency is.

Sometimes the 4100 locking mechanism throws off the alignment because it's either too loose or too tight.

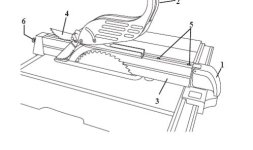

There are two set screws on top of the rip fence near the locking mechanism that you can adjust parallel with. (See number 5 on the illustration)

There is a screw at the end of your rip fence that controls locking pressure. ( See number 6 on illistration)

View attachment 67367096

I hope this helps.

It never ends, does it.

One thing I did notice from the picture I was looking at ... while the glue line didn't show, if you flipped the patch the grain might have flowed perfectly with the existing piece.

Yes, it's trivial. Anal retentiveness does that to a person.

The .008 mis-alignment is unfortunately a pinch at the back, and it’s actually in relation to the miter slot; not the fence. Sorry, my bad. (I attached the dial gauge to a piece of hardwood to fit snug in the miter slot). This is comparing the same tooth in the front as in the back (marking it with a marker). I’ve tackled this issue four times now, and during the last attempt came to think that if the problem is this insanely difficult, the saw housing itself just may not be built properly or there’s more to it than merely loosening the bolts to the housing and pushing on the blade as the manual says. I’ve even had my wife pushing on the saw while I re-tightened the bolts so it didn’t push back into place (doesn’t work). While tightening the bolts, you can watch the dial gauge return to .008 (the bad kind of .008; not the good kind). So I can align the blade when he bolts are loose, but when I tighten them….that’s it…game over…it returns to mis-alignment.

Bosch makes this process so difficult that one of the bolts in the rear isn’t even normally accessible. I had to cut out a space in the plastic casing with my dremel just so an allen wrench could reach it.

As for the rip fence, I had to build my own sliders for it because the ones that come with the fence are so loose in the grooves that the play is insane. This is a common issue with the Bosch 4100 fence and there’s a YouTube tutorial where some Russian guy fixes it with sliders he designed on Blender and printed from a 3d printer. In the end, I did align the fence pretty well using the top bolts.

So I misspoke the first time. The miter slot.The blade front to back is .008 off from the miter slot or the fence?

So I misspoke the first time. The miter slot.

I mean, it’s technically misaligned to the fence as well since the fence is 90 degrees, but yeah, the relevant point here is that it’s off from the miter slot.