- Joined

- Jun 20, 2008

- Messages

- 106,654

- Reaction score

- 98,530

- Gender

- Male

- Political Leaning

- Independent

I want to be in your retirement community. Are they accepting people under forty?Go with your option one.

I am blessed to live in a retirement community that has a woodshop (7,000 sq foot building). We have about any imaginable piece of equipment in multiple numbers along with a good assortment of hand/power tools. Since moving here sold off all my large equipment and just kept what I need around the house.

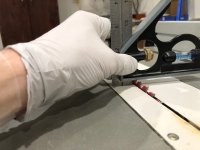

The woodclub also has a group of members who do repairs for homeowners. They just got in a solid oak bed frame to repair.

Hope the repair goes well for you.