- Joined

- Jun 20, 2008

- Messages

- 106,580

- Reaction score

- 98,349

- Gender

- Male

- Political Leaning

- Independent

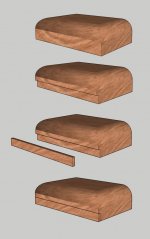

We were able to score an incredible antique solid oak bed frame for a steal which would otherwise be in fantastic condition if not for this damaged section on one of the front feet. One picture for the damaged foot and one for the undamaged foot for comparison:

I don't have the original shard of wood that came off so there's nothing to glue back together. So my first thought was to carve/saw out a clean cross section of the damaged foot, fill it in with the right size piece of unused oak flooring that I have lying around, glue it in place, sand it and finish to match. The problem is that there's no obvious way I can think of to get a solid clean cut (assuming this is even the best solution -- it may not be. If I were dead certain I wouldn't have started this thread).

I can't get it onto the table saw, a miter saw is no good, there's no makeshift edgeguide I can clamp on to use a circular saw, and I have a high powered dremel (1.8 amp) but I'm still at a loss for how I'd get a clean cut with that.

Second thought: rout out that section from above (or, rather, the bottom of the foot) rather than from the side. Problem with that idea is that I only have heavy duty routers (fixed and plunge) when a trim router would almost certainly be more manageable for such a small space. You could technically turn the dremel into a router, but I'm hesitant to use a what is really a glorified crafts tool for a refinishing job.

Thoughts?

I don't have the original shard of wood that came off so there's nothing to glue back together. So my first thought was to carve/saw out a clean cross section of the damaged foot, fill it in with the right size piece of unused oak flooring that I have lying around, glue it in place, sand it and finish to match. The problem is that there's no obvious way I can think of to get a solid clean cut (assuming this is even the best solution -- it may not be. If I were dead certain I wouldn't have started this thread).

I can't get it onto the table saw, a miter saw is no good, there's no makeshift edgeguide I can clamp on to use a circular saw, and I have a high powered dremel (1.8 amp) but I'm still at a loss for how I'd get a clean cut with that.

Second thought: rout out that section from above (or, rather, the bottom of the foot) rather than from the side. Problem with that idea is that I only have heavy duty routers (fixed and plunge) when a trim router would almost certainly be more manageable for such a small space. You could technically turn the dremel into a router, but I'm hesitant to use a what is really a glorified crafts tool for a refinishing job.

Thoughts?