- Joined

- Dec 22, 2012

- Messages

- 66,364

- Reaction score

- 22,109

- Location

- Portlandia

- Gender

- Male

- Political Leaning

- Libertarian - Right

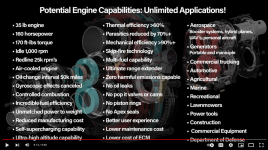

I guess I shouldn't say it's simple without explaining. There has been a new rotary engine developed, that could possible be used for cars. The claim is 160 HP for an engine only weighing 35 pounds. It's all rotary, but requires complicated precision in the manufacturing. Aluminum and ceramic design. I can imagine possible problems and life would be one of them. As long as we use fossil fuels for transportation, it would be nice to have a simpler, more efficient engine in cars and trucks.

I wonder what one of these would cost at high volume manufacturing?

The bearings I think would be the most critical component, as the engine relies on very tight tolerances instead of seals. We have some amazing manufacturing capacity today, but are we ready to mass produce something like this?

I wonder what one of these would cost at high volume manufacturing?

The bearings I think would be the most critical component, as the engine relies on very tight tolerances instead of seals. We have some amazing manufacturing capacity today, but are we ready to mass produce something like this?