- Joined

- Oct 30, 2011

- Messages

- 19,078

- Reaction score

- 6,751

- Gender

- Male

- Political Leaning

- Other

Cutting pvc long-ways is a little different!

Not really. All you need is a way to hold it steady.

Cutting pvc long-ways is a little different!

How is a coping saw going to cut a groove in plastic pipe?

Searching for "edge trim" on Amazon is turning up some good stuff...

Didn't realise that's what he wanted to do. In that case the only thing I would think could work is a rotary tool or a router with a very narrow bit.

use the coping saw to make a pattern/jig to use as a cut guide for the pvc. easy peasy

everything depends on the tools available..

Searching for "edge trim" on Amazon is turning up some good stuff...

They do sell footing for it that's already contoured properly. You could use that as a guide.

they sure as hell do ! I forgot about that important detail ! :doh

I looked online searching for that and they call them horizontal roof closures they make out of plastic now

OK that's a good idea, it may be the best way too, it will eventually rain here ! (We had no monsoon this year).

Anyone else?

would a length of water hose not be adequate to serve as an end cap for that piece of siding?

should be easier to cut/install than the PVC

You can do it by using a sharpie to trace the curves and then cut with a jig saw or a dremel but you will need patience and a steady hand. It might be easier and more practicle to make a straight notch that has a snug fit overall and foam in the gaps.Hi, here's the challnege.

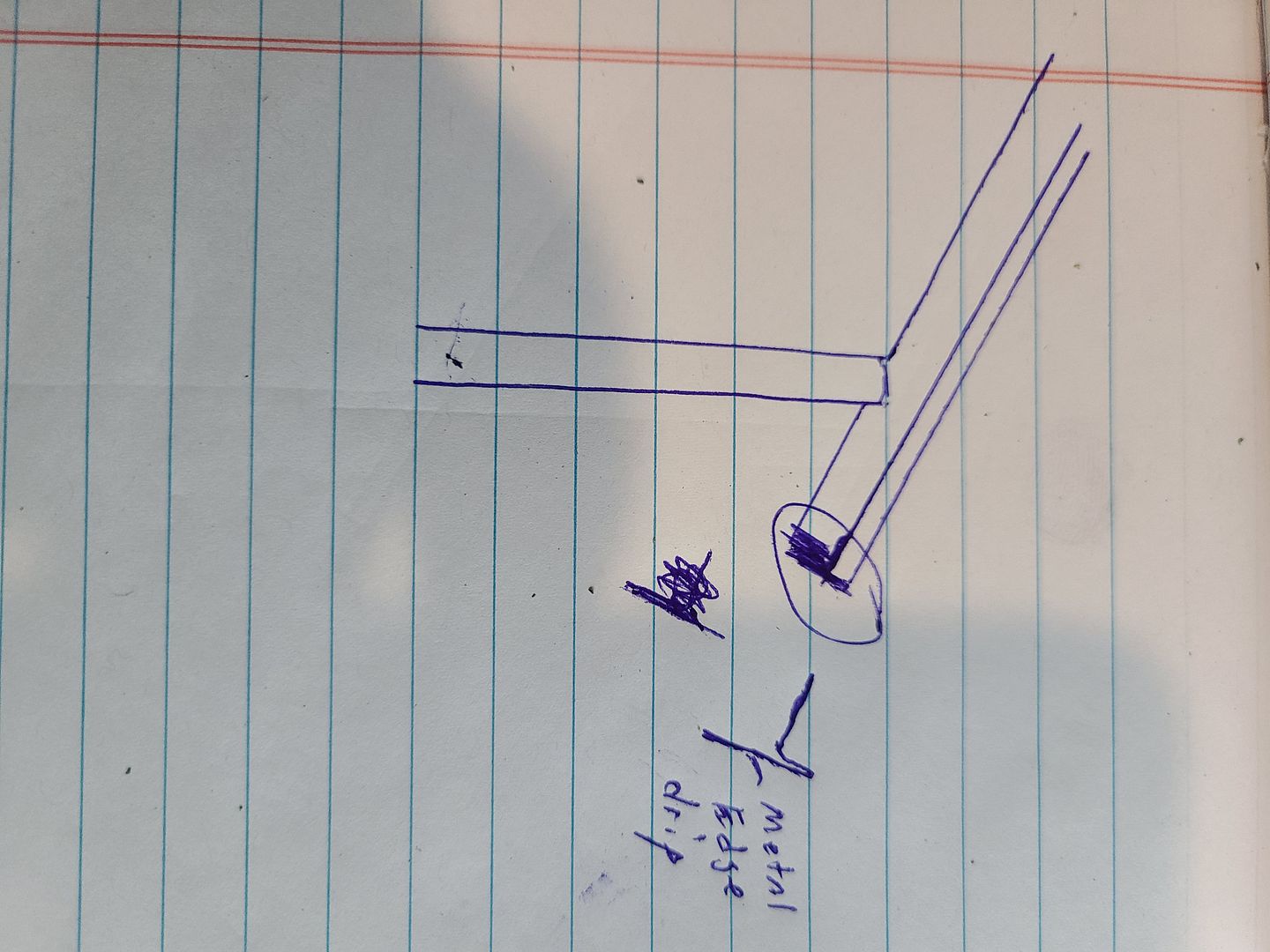

I have a new chicken coop with a corrugated metal roof, e.g.

View attachment 67293328

The corrugated edge runs along the back of the roof of the coop and is about throat height - you can appreciate the risk if someone is distracted or careless.

We tried foam pipe insulation and these worked, the glue was fine and the edge was nicely cushioned but the weather (extreme sun/heat in Arizona, particularly this year) has dried the glue and the foam has begun to decay.

I want to now use pvc pipe, say 1.5" diameter but would love to cut a wavy slot along the edge (rather than just a straight line) to get a very neat fit and make it more secure overall.

I have a Dremel (that I have yet to use!) and wonder is there some way I can use a small power tool like this to cut a wavy line along the length of pipe like this?

Hi, here's the challnege.

I have a new chicken coop with a corrugated metal roof, e.g.

View attachment 67293328

The corrugated edge runs along the back of the roof of the coop and is about throat height - you can appreciate the risk if someone is distracted or careless.

We tried foam pipe insulation and these worked, the glue was fine and the edge was nicely cushioned but the weather (extreme sun/heat in Arizona, particularly this year) has dried the glue and the foam has begun to decay.

I want to now use pvc pipe, say 1.5" diameter but would love to cut a wavy slot along the edge (rather than just a straight line) to get a very neat fit and make it more secure overall.

I have a Dremel (that I have yet to use!) and wonder is there some way I can use a small power tool like this to cut a wavy line along the length of pipe like this?